Saving Etta: Kitchen Update & Installing the Range Hood

Saving Etta: Kitchen Update & Installing the Range Hood

This kitchen was a big deal for me. It was one of those projects I knew would make or break this house. It was also the first time I’ve taken the reins on kitchen design and installed cabinets. As the project was in the home stretch, I spent many hours and late nights working on the kitchen. Today I’m thrilled to give you another update on the kitchen and show you the installation of the range hood (complete with all the mishaps involved). Speaking of mishaps, I have some tips to help you avoid a potentially dangerous and costly mistake when selecting a range hood.

Before we begin, I’d like to say thank you to all my wonderful sponsors on the Saving Etta project. I could not have saved Etta without their help. When you are looking for products that last and perform well, you can rest assured that I hand-selected these sponsors to represent the Saving Etta project.

Where It Started:

If you’ve been along for the entire Saving Etta journey, you may remember the kitchen in the house when I bought it. Then again, you might be like me and need a little memory refresher once in a while. Here’s the kitchen before:

There were only a few base cabinets and five upper cabinets. Lucky thing because it made demolition of the kitchen easier. The first week after purchasing the property, I hauled all the cabinets to the dumpster and started peeling away the layers in the kitchen. It was a lot of work, but so much fun seeing through the decades and discovering old bead board beneath.

The water heater was walled into a little closet in the corner of the kitchen. It was a blast taking a sledge hammer to the wall. Who needs therapy when you can release pent up frustration through demolition?

Unfortunately it wasn’t enjoyable getting the water heater out. My plumber had a tough time removing the water heater from the house!

You might remember asbestos tiles were discovered on the floor and they had to be removed. What was left was a maze of floor joists and pipes where the floor used to be.

I originally hoped to save this room from demolition because it was part of the 1900 structure, but after assessing the lack of crawlspace and a severed structural beam with my architect, we decided it had to be removed.

The picture below is shortly after demolition. The doorway on the right is where the original kitchen entrance was. But, it had been walled off a long time ago to provide space for the refrigerator.

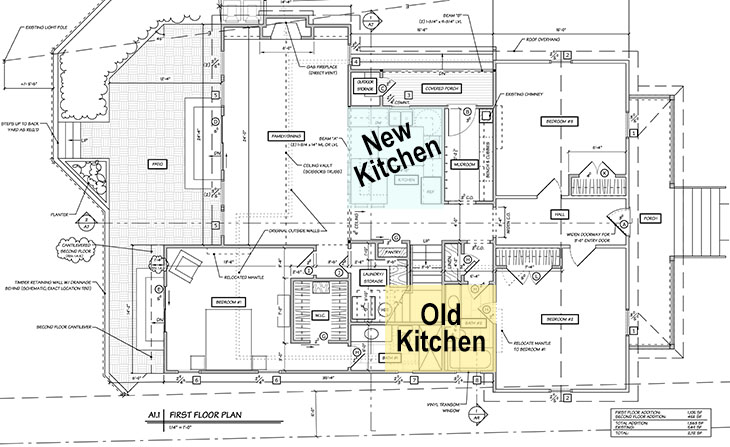

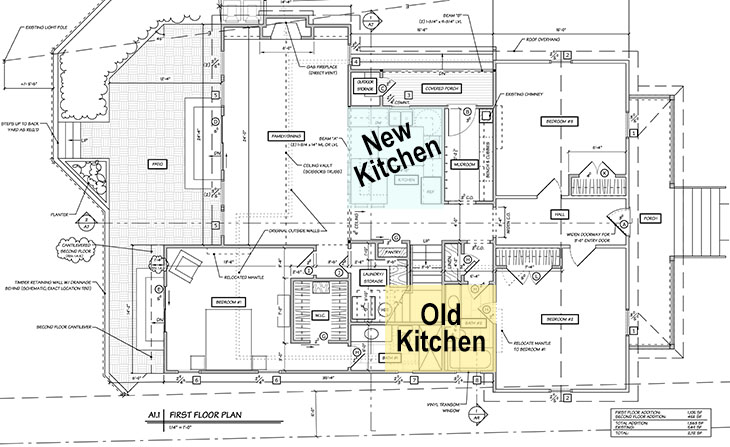

The new kitchen was moved to the other side of the house, as shown in the plans below:

Obviously, after demo, a lot of progress happened to get us to the new kitchen installation. If you want to read the previous updates, here’s what you missed:

Now that you’re up to speed, this is where we left off (right after installing the kitchen cabinets.)

(I’ve included affiliate links for your convenience. I earn a small percentage from a purchase using these links. There is no additional cost to you. You can read more about affiliate links here.)

To protect the wood floors, we laid Surface Shield Builder Boards on the floor. They worked perfectly to protect the floor from spills, dropped tools, and lots of tracked in mud and dirt. It’s amazing how much dirt got tracked into the house. But, when the ground is scraped clean of any landscaping, things are bound to get messy. I eventually purchased two dirt trapper rubber mats and put them by each entrance. This helped limit much of the dirt from coming inside.

Selecting the Range Hood:

Choosing a range hood for the kitchen proved to be difficult because I liked so many of the Broan options. (Broan is one of the Saving Etta sponsors and provided the range hood for this project.)

The first hood I fell for was the Broan RM519004 Stainless Steel range hood. It’s sleek and modern, with a beautiful curved shape.

The style definitely appealed to me because it was different, but the width of the hood is 36″. I was concerned it might look too big in a small kitchen. Ultimately, I think the hood would have worked, but I had already moved on. (I will keep this range hood in mind for future kitchen renovations, because I still think it looks kind of sexy.)

Next I stumbled upon the the B5630SS Broan range hood. It had some curves, but more of a box shape. And the glass hood added some elegance.

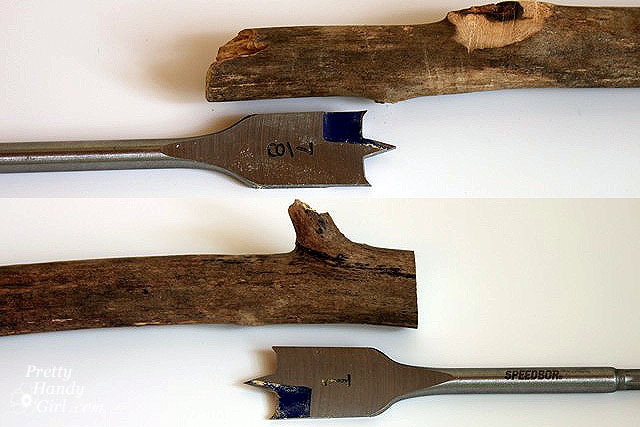

Ultimately I decided against this range hood because I worried the glass would show dust or grease between cleanings. In hindsight, I’m glad I didn’t choose this range hood, because I would have been hit with an unexpected expense. Right before installing the new range hood, my mechanical contractor asked how many CFMs the range hood pulled. “CF-what?,” I said.

What is CFM and Do You Need Make Up Air for Your Range Hood?

CFM is short for cubic feet per minute and it describes the amount of air flow an exhaust fan can pull. Believe it or not, this is one of the most important specifications (besides dimensions) you need to know when considering a range hood. One would think the higher the CFM the better, because it sucks up more cooking odors and steam, right? Not necessarily. Typically 200-300 CFM is adequate for a range hood in a residential kitchen. If you have a commercial stove, or the range hood is mounted further away from the stove top, you may need something stronger. If you need a range hood with a stronger fan (over 400 CFM), you’re required to install a make up air device with an automatic damper. This will add to your expense and requires a licensed HVAC contractor to install it.

For reference, this is the code for exhaust hoods in residential construction:

International Residential Code: M1503.4: “Exhaust hood systems capable of exhausting in excess of 400 cfm shall be provided with makeup air at a rate approximately equal to the exhaust air rate. Such makeup air systems shall be equipped with a means of closure and shall be automatically controlled to start and operate simultaneously with the exhaust system.”

What happens if I don’t add make up air for my range hood?

Stronger exhaust fans can depressurize a house. Resulting in doors slamming shut, air pulled from any cracks or openings in the building envelope, or noise. Some unsuspecting homeowners have turned on their exhaust fan to find it pulls ashes from their chimney. If you don’t have make up air it could create a dangerous back draft situation in the home. This is why it’s important to know what the CFM is for the range hood you want to install. (This article does a good job of explaining the issues with stronger range hoods.)

Luckily the range hood I chose for the Saving Etta kitchen was under the 400 CFM limit. This is the beauty I ordered, a sleek Broan modern stainless steel hood with a square chimney.

No glass to clean and the width is 30″. Plus, the CFM is 370, sufficiently low enough to not need make up air, but strong enough to exhaust cooking steam and odors. This made me happy, especially after all the make up air vents we had to install in the laundry room.)

Installing the Range Hood:

As with many installs at the house, I had to pick and choose which ones to assign to my subcontractors. The range hood was already slated to be installed by my mechanical contractors, so I let them take over installation. I was busy working on another project, but when I came into the kitchen I knew I had to step in and “help.” As before, things were not going smoothly. The first indication that the install may get screwed up was when I found the instructions folded up in the bottom of the product box. I pulled them out and quickly scanned the directions. The second clue was when I found a bracket in the box as well. The guys were trying to figure out how to attach the chimney to the wall (had I not arrived when I did, I’m sure they would have finagled some unattractive solution.) Without an invitation, I took over the role of supervisor and pointed out how the chimney needed to attach to the wall via the bracket in the box. I’m not sure if the guys were relieved or annoyed, but they put up with my directions (thank goodness!)

About Working with Contractors:

Before we go on, I want to point out the fact that these were the so called “professionals”. But, obviously they didn’t know how to install this particular range hood. I chalk this up to lack of experience with this model, not necessarily lack of experience as a mechanical contractor. BUT, they should have been reading the instructions. I want to leave you with this important message:

When you hire a professional, make sure you read the instructions for how the project should be completed. Do your homework and research online so you understand the steps in the project. Speak up if you see something amiss. Just because someone is a professional doesn’t mean they won’t make mistakes.

At the end of the day, the contractors go home. If something is installed incorrectly you’ll be the one who has to live with it. And, unless you are working with stellar contractors, it might be difficult to get them back to your house. (Then again, stellar contractors are oftentimes extremely busy. You’ll need to wait to get back on their schedule.)

We worked together to hang the range hood chimney. The guys had already hooked up the ductwork and painted mastic over the seams (also required by code). The fan motor was plugged into the outlet above the duct.

The hanging bracket was attached to the wall, and then the upper chimney was slid into place over the bracket. Securing the chimney to the bracket was a little tricky because the hole on the chimney has to line up with holes on the bracket. Plus, it was difficult maneuvering a drill against the ceiling. Ultimately, the chimney and range hood were installed. The power was turned on to the hood and…NOTHING! We scratched our heads until I climbed back onto a step ladder and peeked into the chimney. See the problem?

Doh! Somewhere along the way we unplugged the fan and forgot to plug it back in. Luckily we all had a collective laugh about it and then slid the chimney back down to plug it in, then re-attached the chimney to the bracket. My words of wisdom: “Always make sure it’s plugged in!” LOL.

We left the protective film on the range hood, and I’m glad I did because it was easier to clean and protect while tiling. Stay tuned for more updates and the kitchen reveal soon! Next up is tiling the backsplash.

Disclosure: This is a sponsored post for Broan. I was compensated for my time and efforts to promote the Broan products. However, all ideas and opinions are my own. I will always let you know when you are reading a sponsored post. You should also note that I’m very particular about the brands I work with.

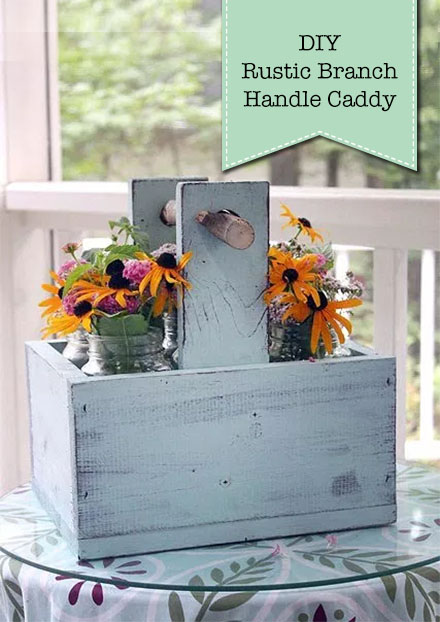

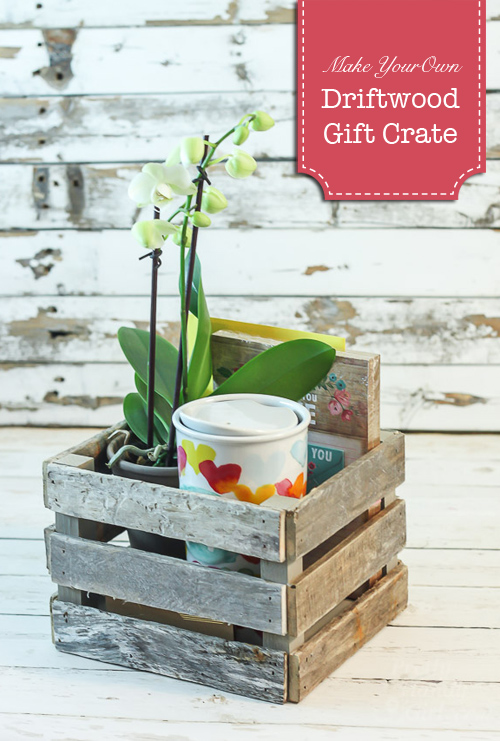

Rustic Wooden Caddy with a Branch Handle

Rustic Wooden Caddy with a Branch Handle How could I say no! It was only $3. I couldn’t leave it at the yard sale in its sad burgundy dust-covered state. I brought it home so it could sit in my garage collecting more dust. (This happens more often than I’d like to admit. It’s a sickness I have.)

How could I say no! It was only $3. I couldn’t leave it at the yard sale in its sad burgundy dust-covered state. I brought it home so it could sit in my garage collecting more dust. (This happens more often than I’d like to admit. It’s a sickness I have.) If you liked this tutorial, you’ll love these other easy DIY Projects:

If you liked this tutorial, you’ll love these other easy DIY Projects:

Hi! I’m Lara, the creator of

Hi! I’m Lara, the creator of

Saving Etta: Kitchen Update & Installing the Range Hood

Saving Etta: Kitchen Update & Installing the Range Hood

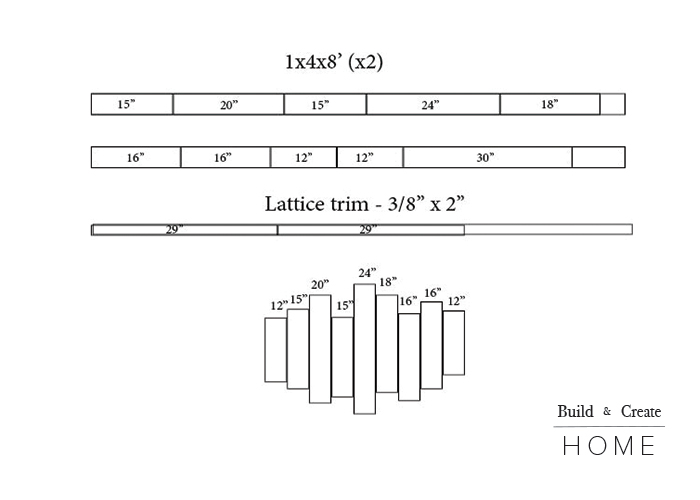

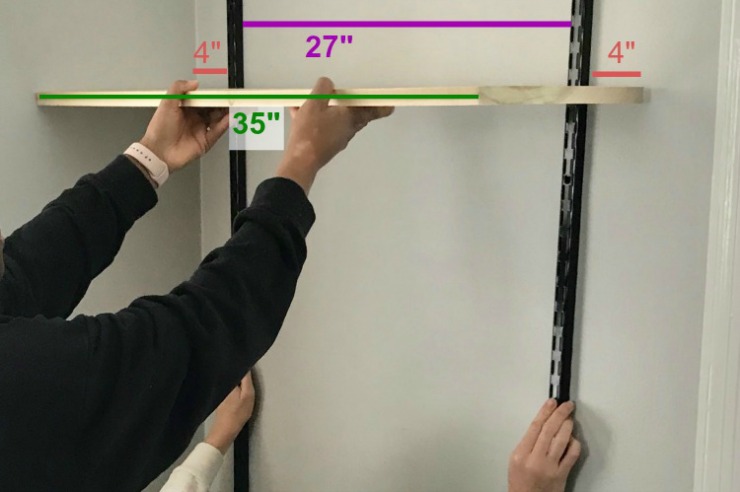

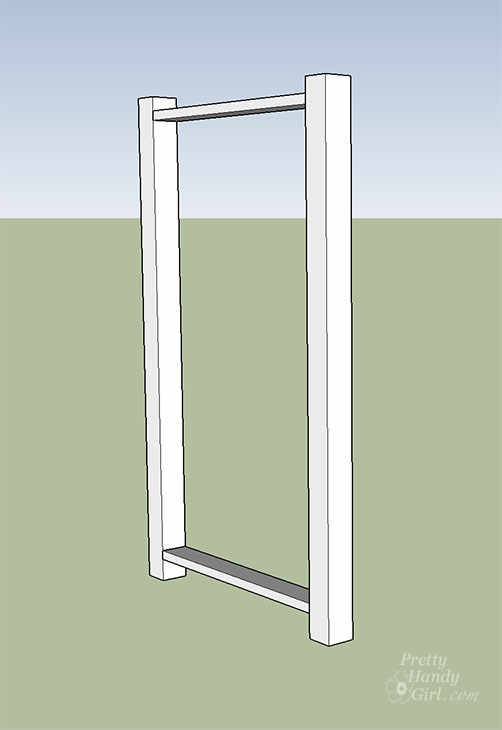

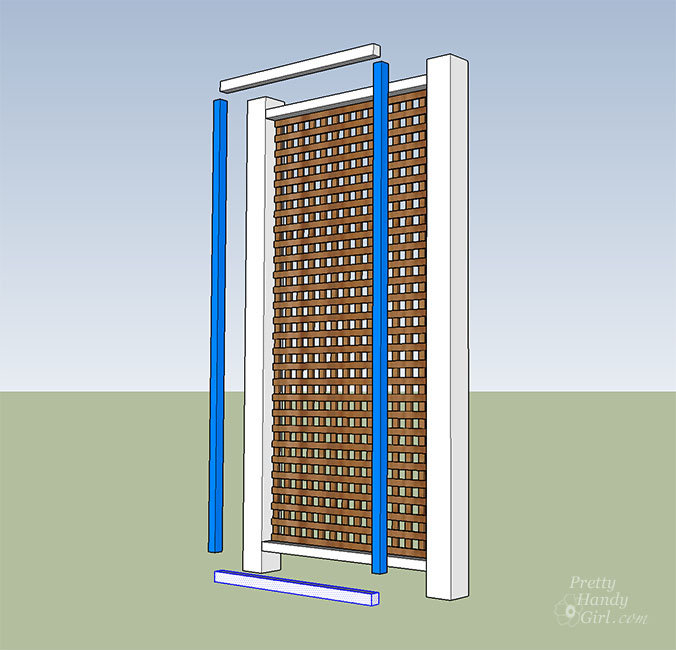

DIY Scrap Wood Shelf Tutorial

DIY Scrap Wood Shelf Tutorial