I’ve always wanted a rustic wood farmhouse table. I wanted a table that looked worn, well-loved and appeared to be over 100 years old. It’s very hard to achieve that look with new lumber. To get that rustic look, you either need old reclaimed lumber or the skills to stain and distress new wood. I chose the first option and bought reclaimed rafters from The ReUse Warehouse in Durham, NC.

They were very rustic to say the least. I was prepared to plane and glue them together myself, but I don’t own a planer (insert sad trombone sound.) Instead, I brought the rafters to Mark Kegler of Kegler’s Woodwerks. Mark has ALL the woodworking equipment and he convinced me to let him glue the tabletop together since I realized I also don’t have 5 bar clamps (Christmas wish list updated now.)

For fun I thought I’d show you the behind the scene pictures of the table top as it was being planed and ripped. That way you can view the process should you decide to piece together your own reclaimed lumber table top.

Behind the Scenes at the Shop:

First they ran a metal detector over the beams and then removed nails with an extractor.

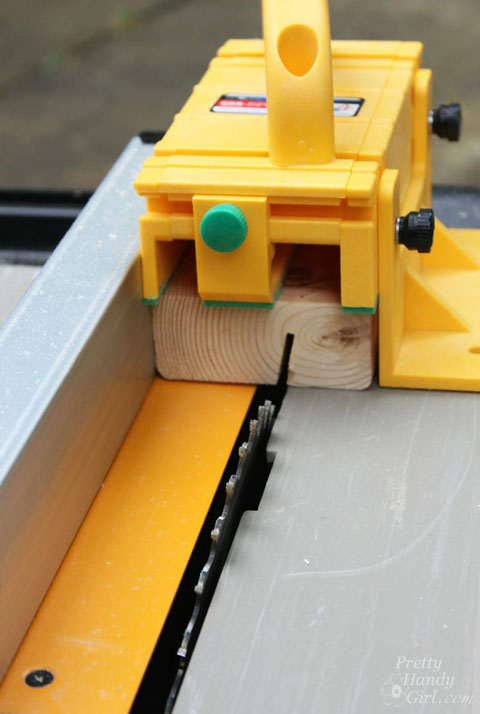

Next, the rafters were fed through a planer to give them all a uniform thickness.

It was like Christmas morning watching the wood as it came out and I could see the of the beautiful grain revealed.

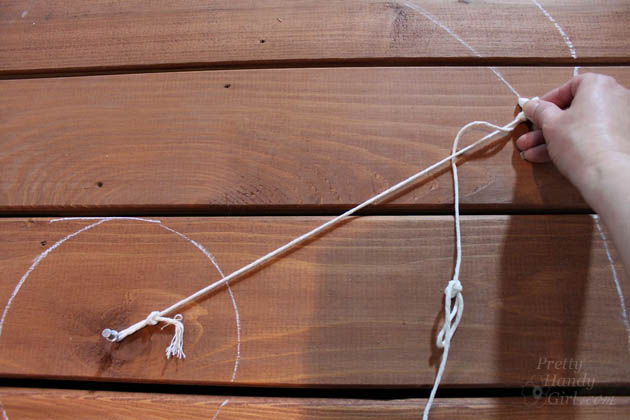

Mark and Randy used a straight line rip saw to cut the edges straight with the exception of two rafter edges that would be used for a live edge on the table. I was able to salvage the edges that they ripped off for later use.

The boards were glued with wood glue and clamped together. Then they were left to cure overnight. In the morning, the short ends of the table were cut square.

Back at home I built the table base (the apron and legs).

Finishing the Reclaimed Wood Table Top:

Remember the salvage I kept from Mark’s shop? I used it to cap the table as edge band to hide the end grain. Hold the edge band up against the end, mark and cut the excess off.

Add wood glue to the inside of the edge band. Read more