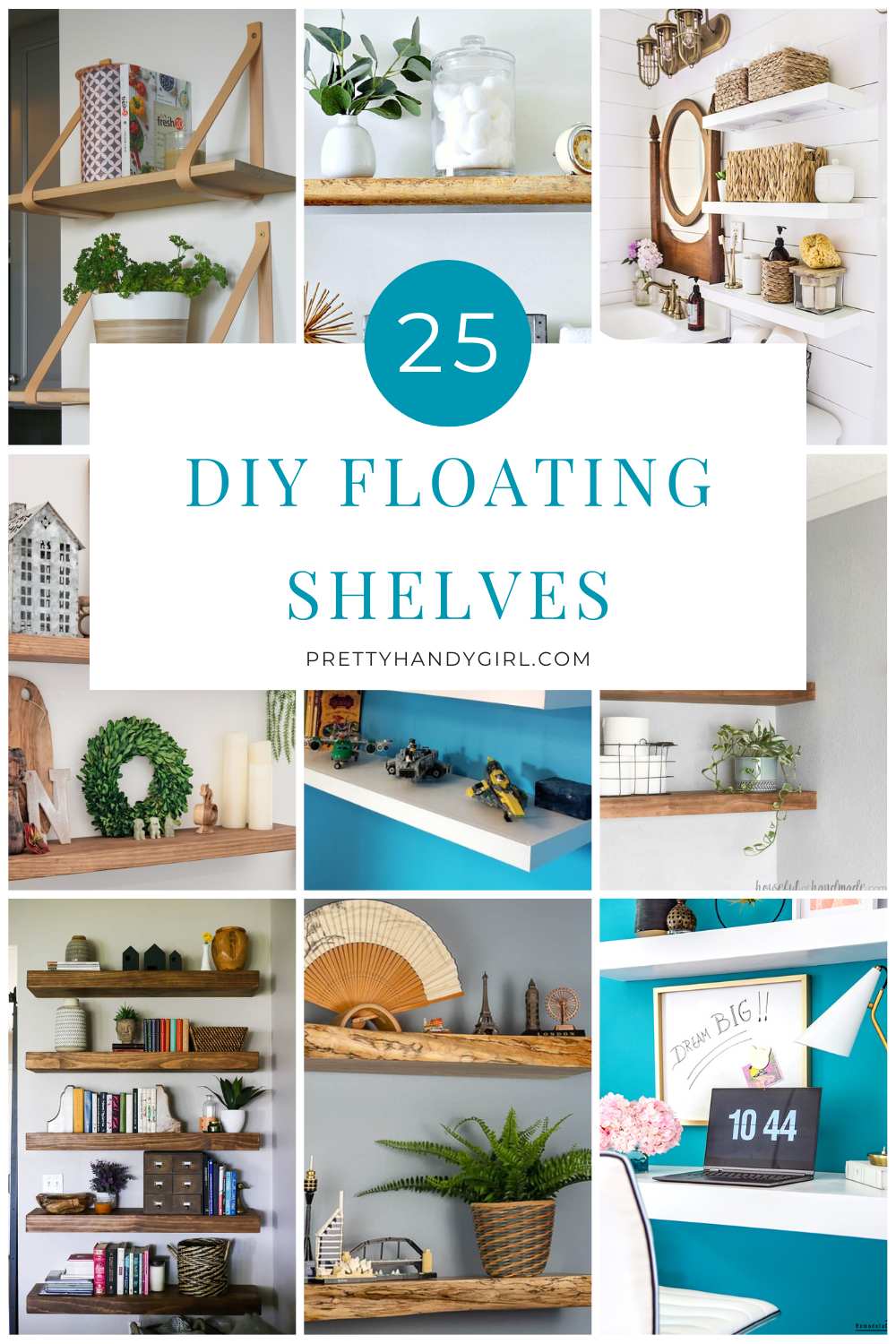

Discover 25 stunning DIY floating shelves with easy-to-follow step-by-step tutorials. Transform your space with these creative ideas.

From rustic to modern designs, build floating shelves to fit any home decor style. All you need are a few tools and supplies and you can easily make your own.

DIY Floating Shelves

Today, we’re talking all about DIY floating shelves – the perfect blend of functionality and aesthetics that can transform any room from ordinary to extraordinary!

If you’ve been looking for fantastic DIY floating shelf ideas, you’re in the right place! Whether you’re a seasoned DIY expert or just getting started on your creative journey, these clever and versatile shelving solutions are perfect for any size room. Shelves will not only declutter your space but also showcase your cherished knick-knacks and decor in an organized manner.

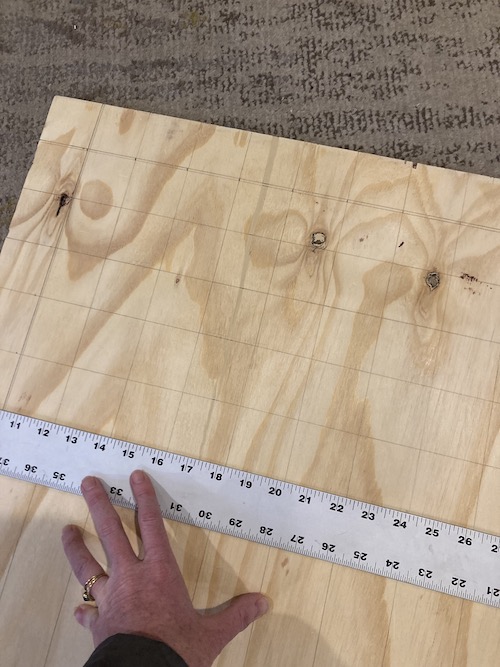

Before we get to the inspiration projects, let’s talk about the most common power tools and supplies you may need to build your own.

Common Supplies Needed for DIY Floating Wall Shelves

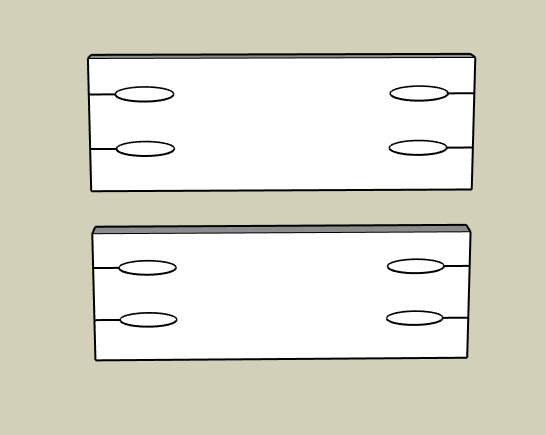

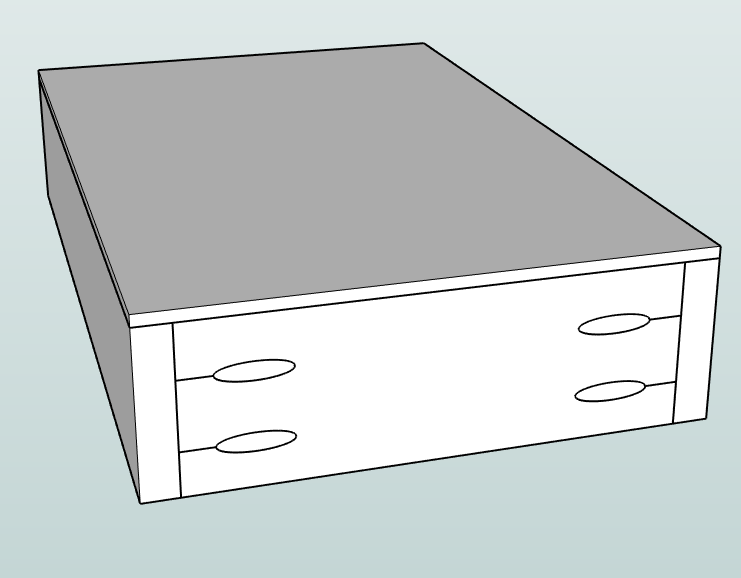

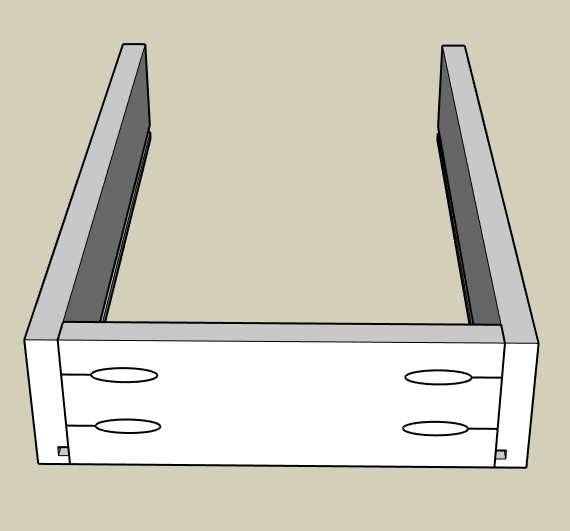

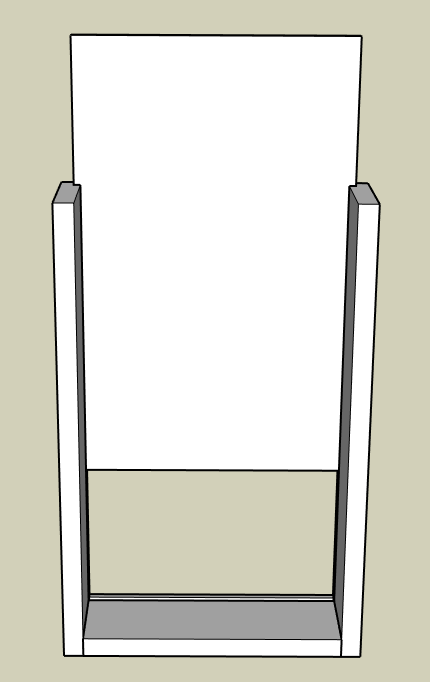

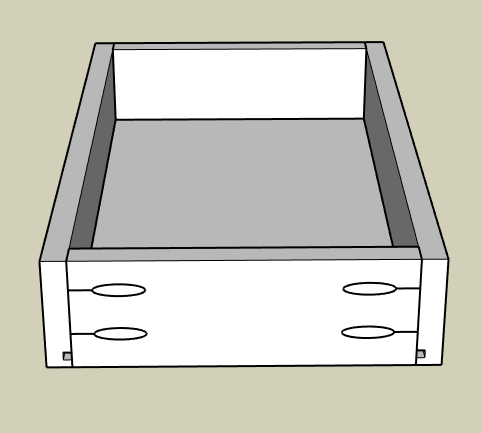

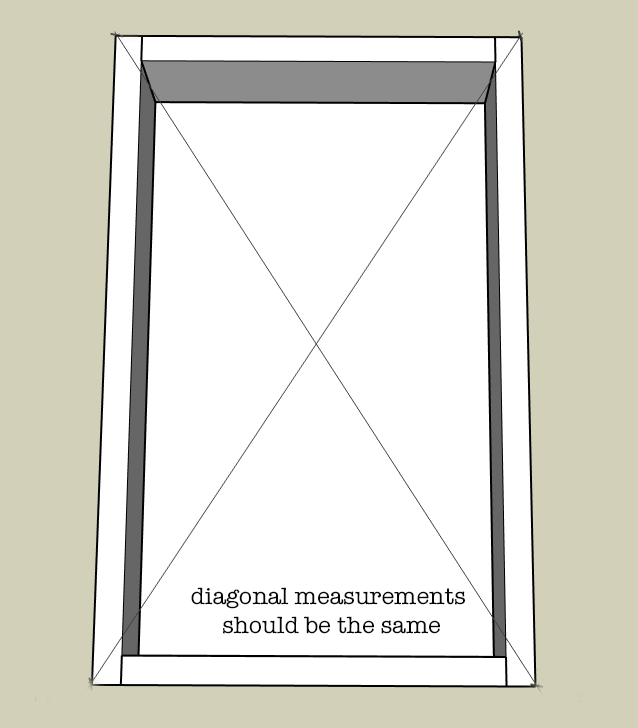

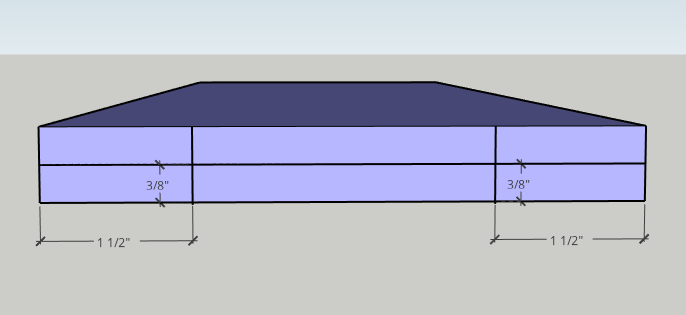

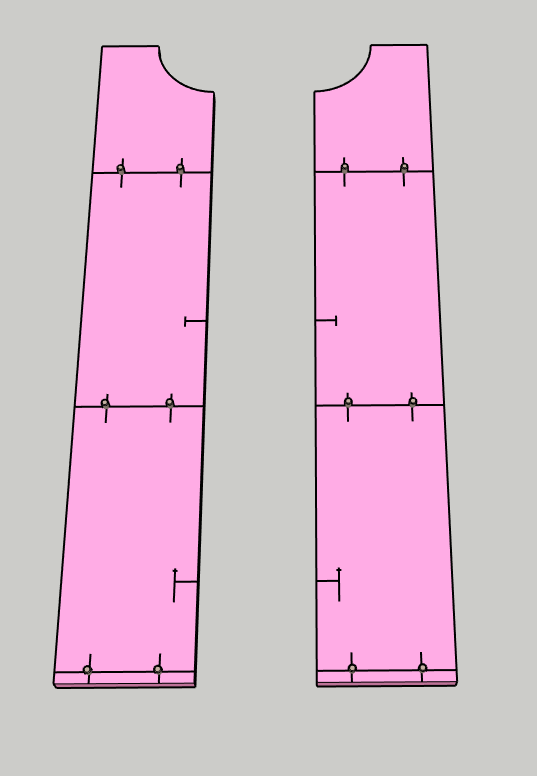

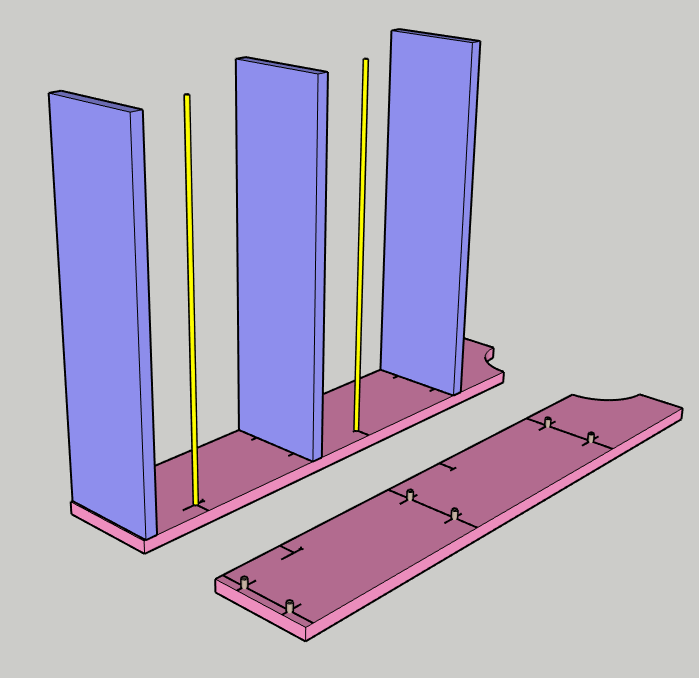

- Pieces of Wood for Shelves (top and bottom pieces)

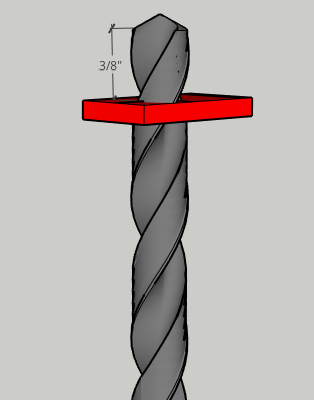

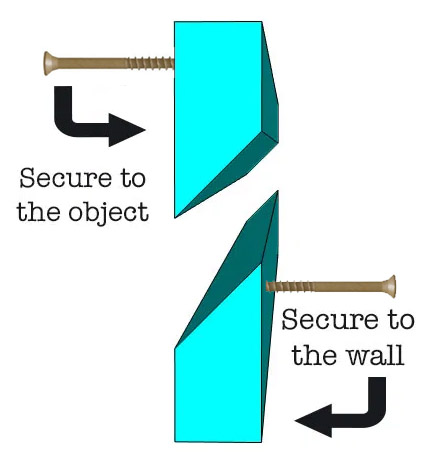

- Shelf Supports

- Wood Glue

- Wood Filler

- Wood Screws

- Brad Nails

- Drill – to drill your pilot holes

- Stud Finder (optional but you can find the wall stud so much faster)

- Pocket Hole Jig (makes it so easy to make pocket holes)

Now let’s take a look at this great collection of spaces with added floating shelves.

Picture ledge floating shelves built into a nook are the perfect space-saving idea! Display family photos, or other mementos.

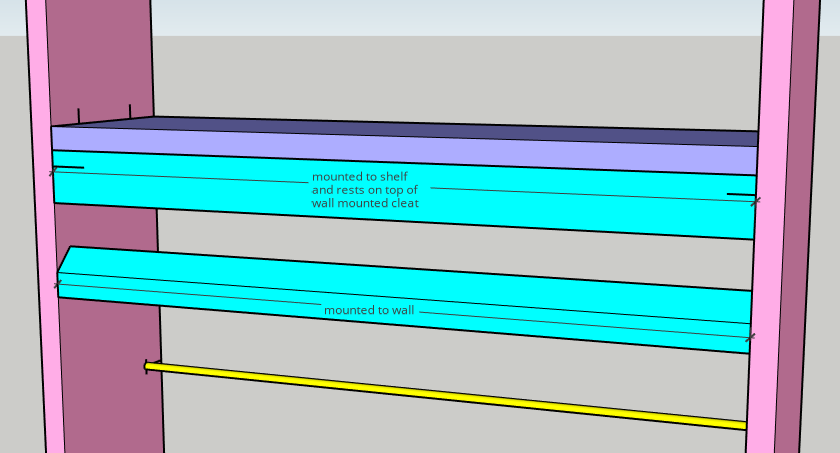

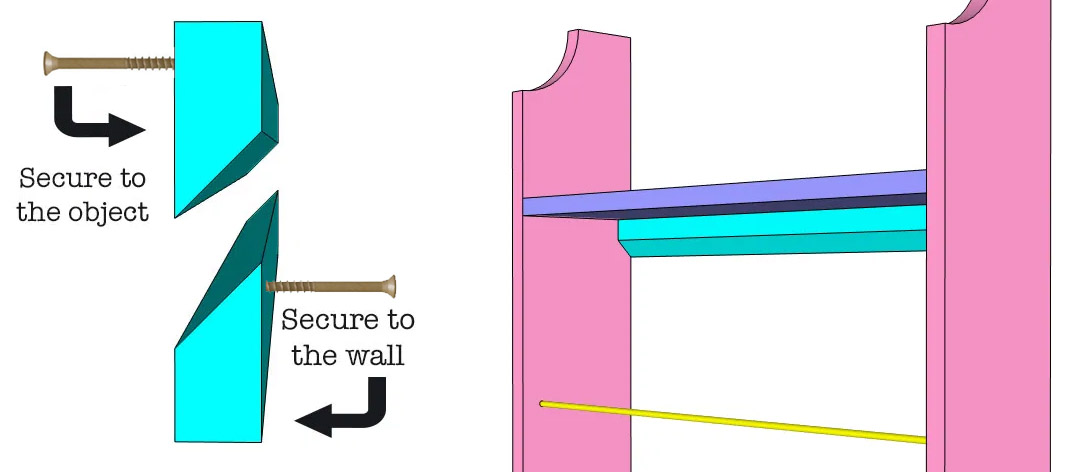

I built these floating shelves with LED lighting and they are so cool! These shelves are super strong and have a modern black finish. Plus, you can make them almost entirely with scrap plywood.

Anika from Anika’s DIY Life built a clever DIY Floating Ladder Shelf for her bathroom. This is another space-saver idea perfect for guest towels and toiletries.

Check out this creative floating TV shelf made specifically to hold your TV and components! It’s perfect for small spaces and has a sleek look to it. Plus, it’s a simple build done in about 2 hours.

Warm wood stained shelves are the perfect addition to a small bathroom and fit great above a toilet, which can be a difficult space to decorate. Get the easy step-by-step tutorial to make your own.

Learn how to install glass window shelves above your kitchen sink or any other window in your home. It’s the perfect way to give your favorite plants extra light and they look great in the window too. Something pretty to look at while you’re washing dishes!

DIY Picture Ledge Shelves can be hung in a living room, bedroom or any room where you want to add a bit of personality. The ledge style shelf gives a modern look to the classic wood design.

Kati from Houseful of Handmade shares her tutorial for easy floating shelves that are budget-friendly too.

Add texture and dimension to a small space with this floating shelf tutorial. These shelves would be a great addition to an office with plenty of room for books and other office supplies.

Floating shelves above a desk work perfectly in a child’s room for a dedicated homework station, or to display their favorite collectibles.

Looking for a modern idea for simple DIY floating shelves? Be sure to check out these stunning shelves from Lindi & Russ!

You can add DIY floating shelves the easy way with this tutorial from Allison with Upright and Caffeinated.

Live edge floating shelves are a unique option for any style home. The warm, rich wood tones add texture and dimension on a budget!

Check out these tips for adding floating shelves on an uneven wall. The floor-to-ceiling shelves create a stunning focal point with tons of room for storage.

Farmhouse style floating shelves are a popular option that can be decorated for any season or holiday.

Learn how to make floating shelves the easy way! Handan and Greg share their tips!

Floating window shelves bring in that wow factor and plenty of light to grow plants.

Learn how to make desk floating shelves that take up limited space and a built-in work station.

Toni from Girl, Just DIY added several office floating shelves above her desk for storage and display purposes.

Open shelving in the kitchen is a popular option for so many reasons. It makes a room appear larger and is a budget-friendly option to standard cabinets.

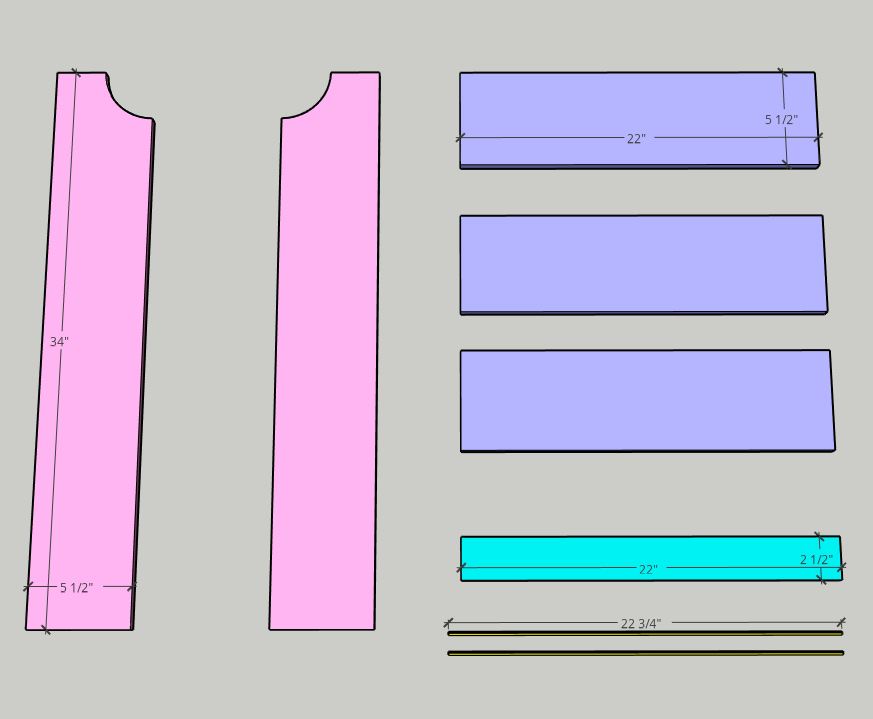

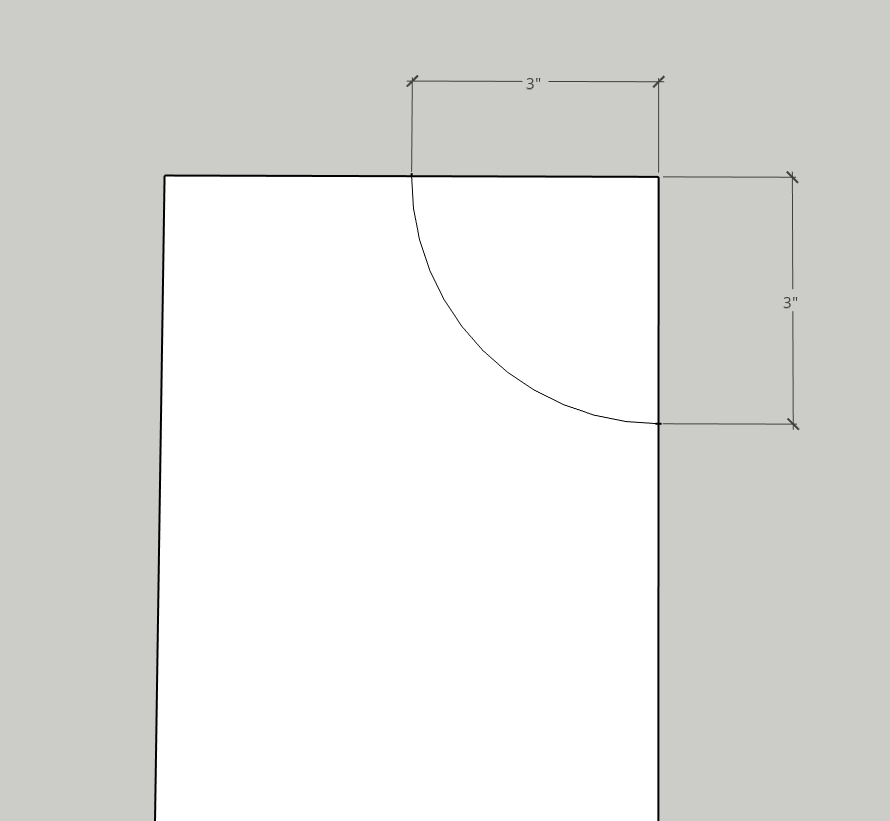

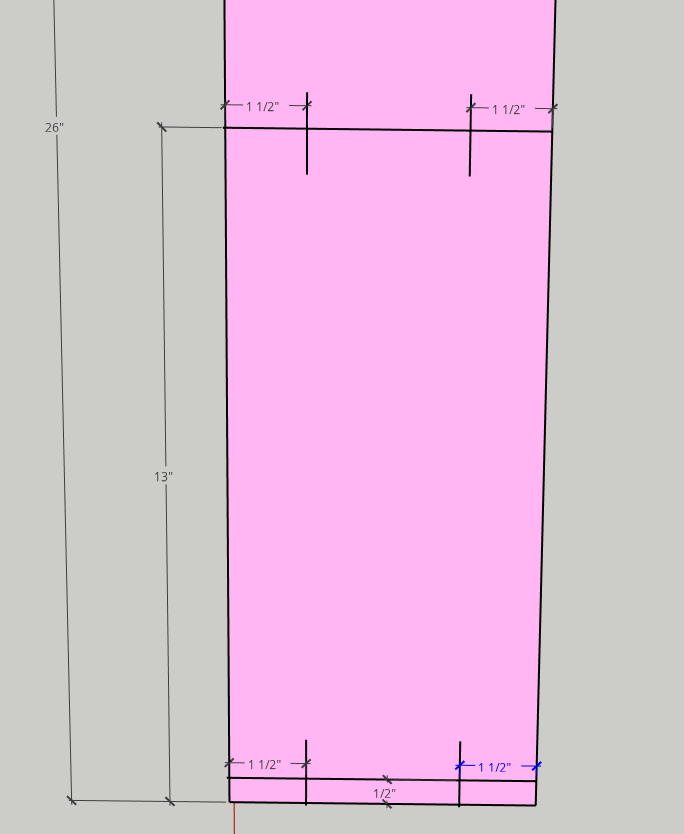

Plywood floating shelves are cheap and easily found at your local hardware or big box store.

Kristi from Chatfield Court shows us how she built faux floating shelves for her bathroom. A simple project that you easily build in just a few hours.

Every bathroom-or room for that matter-can use extra storage. Floating bathroom shelves are the easiest way to add storage for cheap.

Wendy from My French Twist made the coolest leather strap floating shelves for a small blank wall in the kitchen. These have a boho design that are incredibly easy to DIY.

Another unique shelf idea for a small space is to build floating corner shelves. You can get the tutorial and tips for installing them from Angela Rose with Angela Rose Home.

So what do you think? Are you ready to add some DIY floating shelves to your home? Let me know if you give any of these ideas a try. As always, thanks for reading!

Please remember to share on Pinterest to inspire others as well!