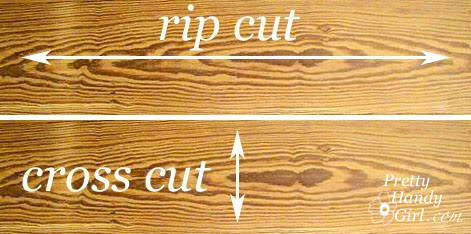

Making large and small rip cuts doesn’t have to be a difficult or calculated process. With this inexpensive and easy to make DIY track saw jig, you will be making rip cuts quickly and easily with your circular saw!

DIY Track Saw Jig for your Circular Saw

DIY Track Saw Jig for your Circular Saw

Hi! It’s Kristen, from In Her Garage, and today I am going teach you how to make a DIY Track Saw Jig for your circular saw. It’s basically a super simple circular saw cutting guide to make rip cuts much easier for you. No more accounting for the saw’s base plate width or spending a ton of money on fancy, brand name guides. This will be an easy drop and clamp design that is foolproof! Let’s make it!

Materials:

(I’ve included affiliate links for your convenience. I earn a small percentage from a purchase using these links. There is no additional cost to you. You can read more about affiliate links here.)

- circular saw (that you will be using this saw guide for!)

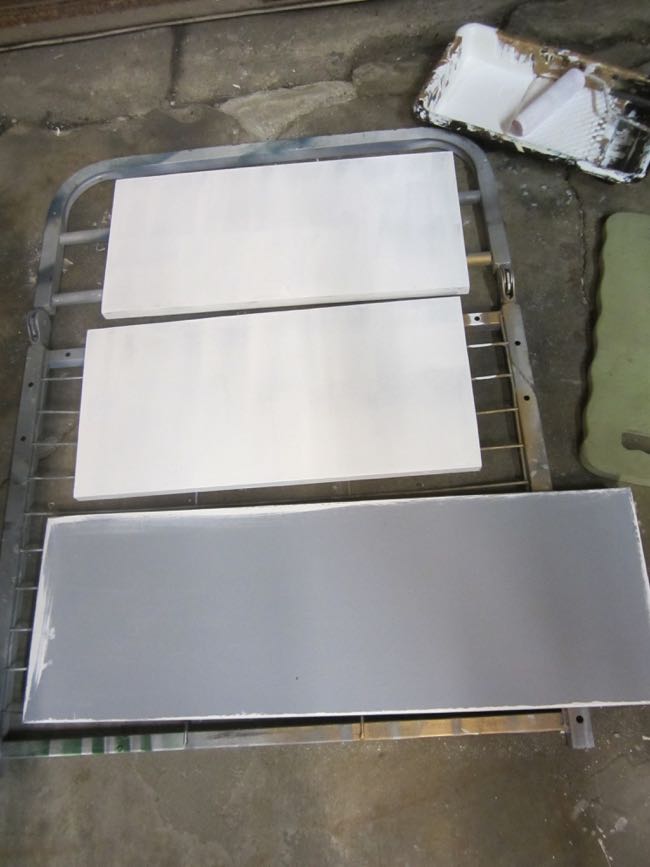

- 1/4″ x 2′ x 4′ MDF hardboard panel

- wood glue

- clamps

Instructions:

1. Measurements for the track saw base panel

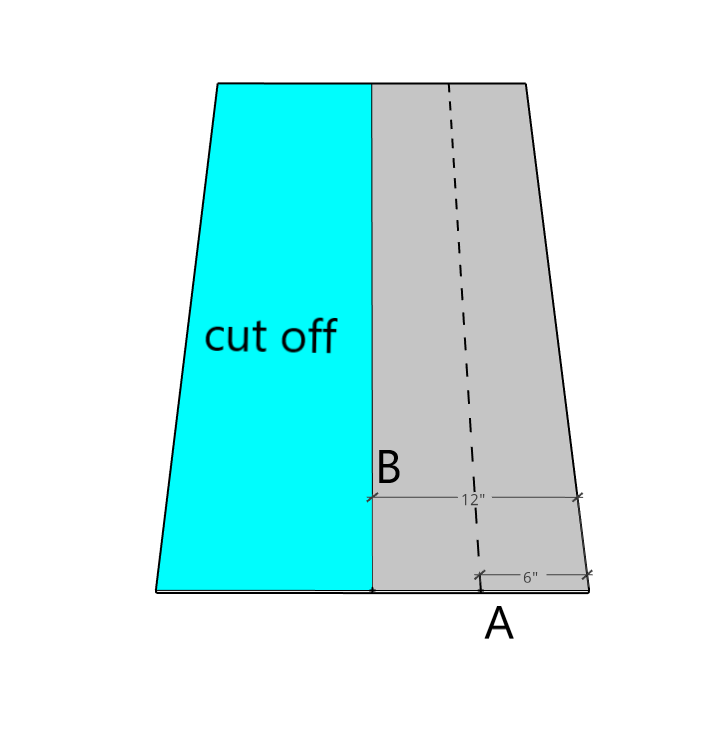

Create 2 lines running the length of the hardboard panel and label them “A” and “B” as indicated in the diagram below.

- “A” measures 6″ from the edge – this measurement is approximately the width of most circular saw baseplates

- “B” measures 12″ from the edge – this measurement is approximately the width of the entire circular saw and will be the end width of the track saw jig.

2. Cut the excess off of the base panel

Clamp a straight edge (or any straight piece of scrap board) lined up against line “B”. Set your circular saw base plate against the straight board and cut along the length of the hardboard to cut this excess off. You will use the freshly cut edge of the excess in the next step.

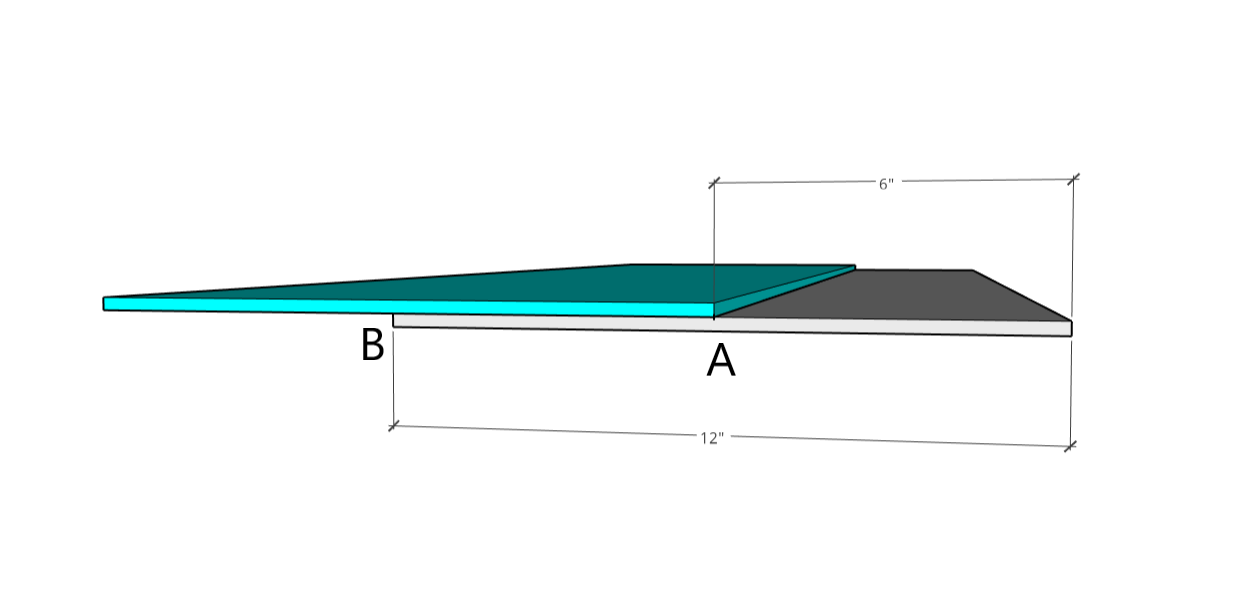

3. Creat the track saw cutting guide

Apply wood glue between lines A & B of the track saw base panel (as shown above.) Do not apply the glue too close to line “A” or the glue will squeeze-out in the next step. Collect the excess piece of hardboard you just cut off and align the freshly cut edge up to line “A” of the base panel.

Clamp and apply weight over the top of the two panels. Wait approximately 15 minutes for the glue to cure and adhere the two pieces together.

4. Cut the straight edge guide

Position your panel so the 6 inch “A” section overhangs off the edge of your work surface (this is the edge you used to measure lines “A” and “B” from.)

Rest your circular saw’s base plate against the top glued piece using it as a straight guide. Make sure your saw blade will avoid your work surface when cutting. Now cut along the length of your panel.

This will create an edge that is exactly the width of the inside base plate to the inside of the saw blade.

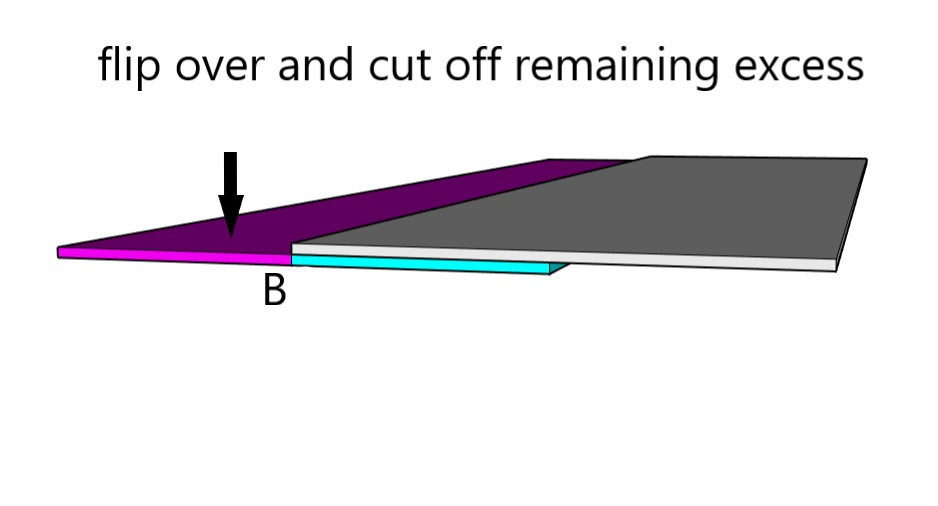

5. Cut off the excess from the back of the jig

Flip the jig over and cut off the excess material that extends beyond line “B” shown below.

Do not cut any further into the jig than line “B” because your DIY Track Saw Jig well be too narrow. You will need this extra width to clamp the jig to any material you plan to cut. If your jig is too narrow, the saw’s motor will catch on the clamps.

I’ve created a video to simplify the instructions for you:

Now you have your own DIY Track Saw Jig for your circular saw! How easy was that?

Using the jig is even easier. All you need to do is measure and mark the surface you plan to cut. Then align the edge of the track saw jig with these marks and clamp down. You’ll have a perfectly straight guide for the circular saw to travel along. Just be sure to take into account which side of your measurement you want the saw blade to cut on and position the jig accordingly.

Great Job!!! Now just store this jig in a place that is easily accessible because you will use it A LOT!!

Helpful tip from the Pretty Handy Girl: Buy a panel of foam insulation from a big box store and cut your plywood on top of it. The foam panel provides a firm surface for the entire piece of plywood and eliminates any falls, pinches, or board balancing you may need to do.

If you enjoyed this tutorial check out my DIY Toy Chest and 1 Drawer side table. The DIY Track Saw Jig will come in really handy for making these gorgeous pieces.

About Kristen:

About Kristen:

Hi! I’m Kristen, from In Her Garage, and I am a self-taught woodworker and DIY fanatic from Minnesota where I live with my husband and our two daughters. Between being a wife, mom and, registered nurse, I try to make as much time for DIY as possible. My love for building came after our family built our current home in 2015. After we moved in, we needed furniture and instead of spending massive amounts of money to order the pieces we wanted I decided that I would build them myself. I started with a buffet table plan from the fabulous Ana-white and quickly set out to remodel my entire home office.

Since then I have started a side business building furniture for the people in my community. I love hearing my clients talk about the pieces they wish they had whether it be a rustic buffet table, a one drawer side table, or a toy box and then making it a reality for them. While starting my small business it made perfect sense that I would document my building journey so I simultaneously launched the In Her Garage blog and I love sharing my plans, tips and tricks.

Making something beautiful with your own two hands through a little preparation and determination is an amazing feeling and I hope to bring inspiration and know-how to those looking to tackle a big or small project.

I am so glad that you found me here and please feel free to connect with me on Pinterest, Instagram, Facebook, and Youtube to see what I am working on right now.