How To Build a Sliding Mirror Door

How to build a sliding mirror door:

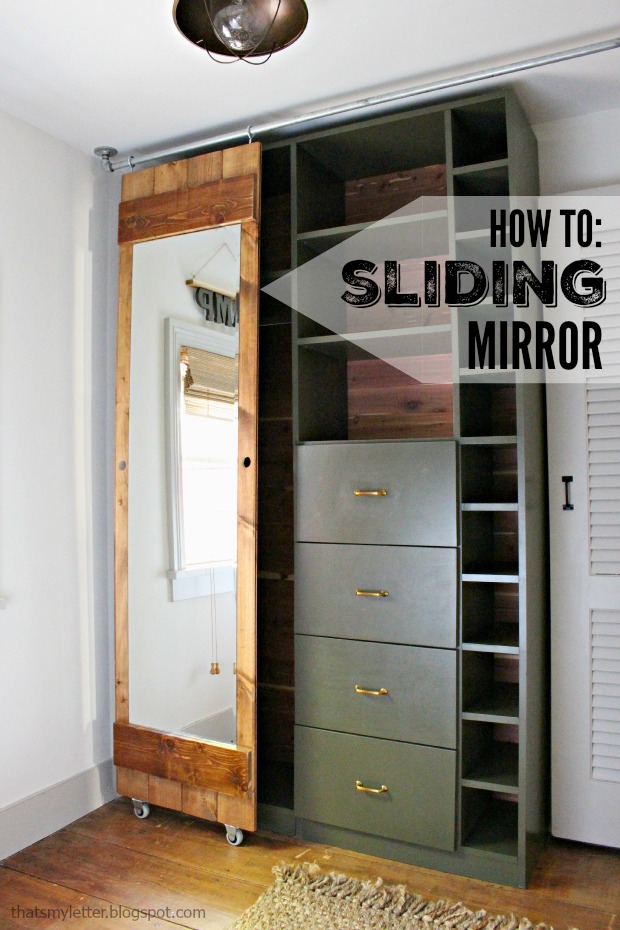

Hello Pretty Handy Readers! Jaime here from That’s My Letter and today I am sharing a sliding mirror project that is the finishing touch on my newly made over walk-in closet. I will show you how to build a sliding mirror door using wood, wheels and pipe fittings.

This sliding mirror is my solution to a small walk-in closet with no wall space and no back of the door option for a mirror. The mirror slides across the room on stationary wheels and a galvanized steel pipe track.

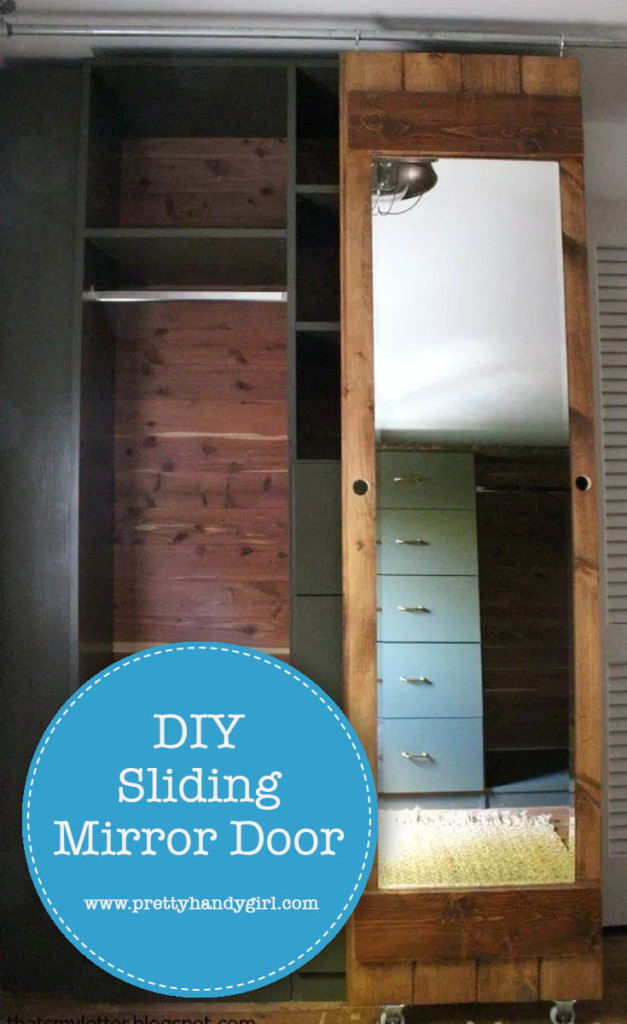

My pipe extends beyond the built-ins (mainly because that’s the pipe I had on hand) but this also allows for full access to the built-in compartments.

In the photo below you can see the pipe extends beyond the built-ins at the ceiling:

Simple finger pull holes allow you to glide the mirror along the pipe. You could get fancy with hardware here but I took the minimalist approach.

Stationary wheels keep the mirror in place while eliminating the need for any lower track system.

Hello super slim profile! The whole mirror and wood support is only 1 1/2″ thick so the mirror does not protrude out into the room.

Ready to make this clever sliding mirror? Let’s get to it…

Materials:

- 4 – 1x6x8 tongue and groove planks

- 1 – 1x6x6 pine board

- 1 – 1×2 about 16″ scrap pine board

- 1 – mirror

- 1 1/4″ brad nails

- 1 1/4″ wood screws

- 2 – screw eyes

- 2 – 2″ stationary wheels

- stain

- foam brush & paper towel

- liquid nails construction adhesive

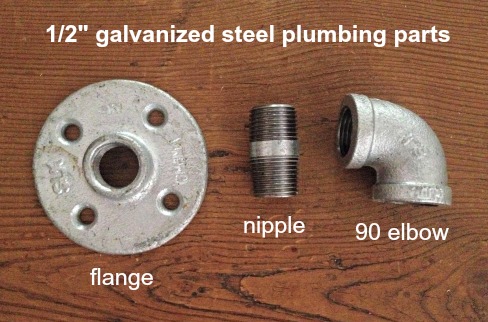

- 2 – floor flange (1/2″ galvanized)

- 2 – nipple (1/2″ galvanized)

- 2 – 90 elbow (1/2″ galvanized)

- 1 – 1/2″ galvanized pipe @ 72″ long

- mollies & 1 1/2″ screws

- painter’s tape

Tools:

- nail gun

- drill & drill bits

- wood glue

- sander & sandpaper

- saw

- hammer

- measuring tape

- pencil

- 1 1/4″ spade bit

Below are the plumbing parts used for this installation (buy two of each):

Before building the mirror, measure your floor to ceiling height then subtract the wheel height, the screw eye height and plumbing parts. This will vary for each installation but from there you can determine the length of the boards.

Step 1:

Cut tongue and groove boards to length. Attach the 1×6 horizontal board across planks at both ends using wood glue and 1 1/4″ brad nails. But, be sure to leave space for the mirror between the 1×6 boards:

Step 2:

Flip over and add 1 1/4″ countersunk screws into planks and 1×6 for additional support:

Step 3:

Sand smooth:

Step 4:

Apply stain with foam brush and wipe excess. Let dry. If desired seal with poly.

Step 5:

Squeeze out a generous amount of liquid nails construction adhesive:

Step 6:

Press mirror in place and let dry following product guidelines:

Step 7:

Pre-drill holes and insert screw eyes:

Step 8:

Attach a horizontal 1×2 at back using wood glue and countersunk 1 1/4″ screws. This will give you a place to secure the wheels. Pre-drill and attach wheels to bottom of boards:

Step 9:

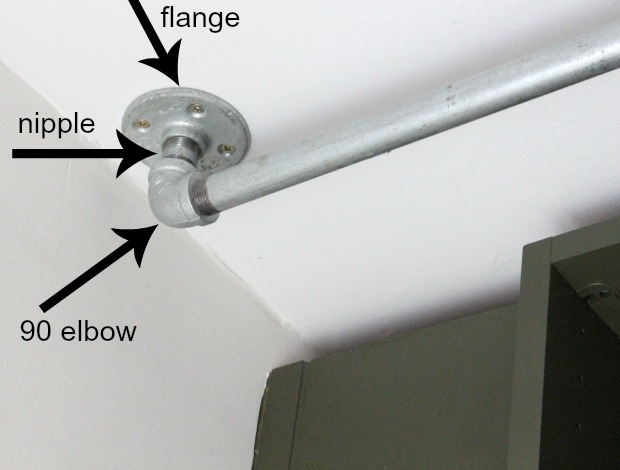

Moving on to the hardware installation. Determine placement on the ceiling (my hardware is mounted about 6″ out from the built-ins). Hold flange in place and mark holes with pencil, pre-drill holes for mollies then hammer mollies in place. Then, screw flange in place and attach nipple and elbow:

Step 10:

Temporarily screw pipe into installed elbow and then add fittings at the other end. This is only temporary at the moment just to mark the position on the ceiling:

Step 11:

Mark the flange position on the ceiling and pre-drill for mollies. Insert mollies with hammer. Then remove the unattached fittings and unscrew the pipe.

Step 12:

Slide the pipe through the screw eyes on the door then screw pipe into fittings at far end:

Step 13:

Attach fittings to open pipe end and screw flange into position in the ceiling. ** Be certain to check door function before adding all screws. Then, you can adjust the height by screwing or unscrewing the screw eyes if necessary.

Step 14:

Determine position for finger pull. Wrap side of plank with painters tape to prevent tear out and use a 1 1/4″ spade bit to slowly drill holes then sand smooth:

The sliding mirror door is complete.

Conclusion:

Hope you enjoyed this alternative use of plumbing parts combined with a mirror on a closet. This sliding mirror project could work in a variety of situations, think beyond the standard mirror installation and you might surprise yourself! No you know how to build a sliding mirror door.

Pin for later!

How well do the eye bolts work? I’ve tried building something similar but with 3/4″ pipe and 1″ tees, but there is too much lateral movement when the door is moved and the tee catches on the pipe, preventing the door from moving. I think the eye screws might work better as that lateral movement would be significantly less, but I’m also using an actual barn door, not something custom-built, so weight might be an issue, too.

Thanks for any comments. Great work, BTW!

Hi Jaime! I’m very interested in this DIY, what is the average cost of that project?

Thanks a lot!

I did NOT expect to actually find what I was looking for when I googled “how to build a mirror barn door.” This is a much simpler and more feasible version of the solution I was trying to come up with for two odd-sized bedroom closets I framed in on either side of a refrigerator nook in the kitchen on the other side of the wall. I’m especially thrilled to find my solution designed by another female renovator. All this just to say: Thank you for existing. Best wishes! Christy

this is my new email.

Very cool idea! And afforadable. Love it!!

This is so clever! Featured on Ana-White.com today! We always enjoy both of your ladies projects, thanks for sharing with the rest of us!

Thanks ladies.

Just great. I will be following you

I want to know about the noise… does this make a terrible metal on metal noise or is the trick to have the eyes only looped through the pipe and not actually hanging on it?

Hi Janet, yes the trick is to have the pipe run precisely down the middle of the eyes which is why it’s important to adjust the eyes (screwing in more or less) before attaching the final flange to the ceiling. My floors are extremely uneven and not level so mine makes noise at the far end but we hardly ever glide it down to that end.

It took me a while and google to figure out WTH are mollies (since there are none in the pictures). Ahhh … screw anchors. Molly seems to be a regional term for those. {Don’t fret … the guys here call structural lag screws “Germans” … because the box they came in was from Germany.}

This is beautiful, great tutorial, thanks for sharing this!

Amazing….I priced the hardware for slider 189$ the door 129$. Theae were sale prices!

omg- I just found your page on FB and will be following you. I only saw a few of your posts and I am already excited to see more.

Thank you!