Hey, you came back! So glad you weren’t scared off by my toilet repair post. Well, congratulations to you for sticking with me and wanting to learn how to fix your toilet.

In Part 1 we learned how to replace the flush lever. If you found it easy, I know you won’t find today’s tutorial too difficult. And then, you will certainly be able to replace the overflow tube and flapper in my next post.

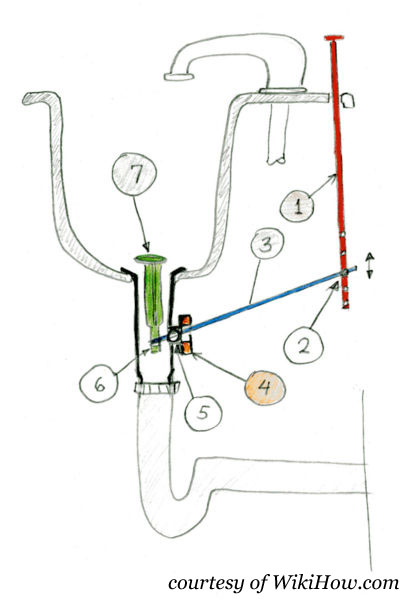

In review, here is what your toilet tank parts are:

Here is the kit I recommend you purchase (costs about $20):

And here are the tools you will need:

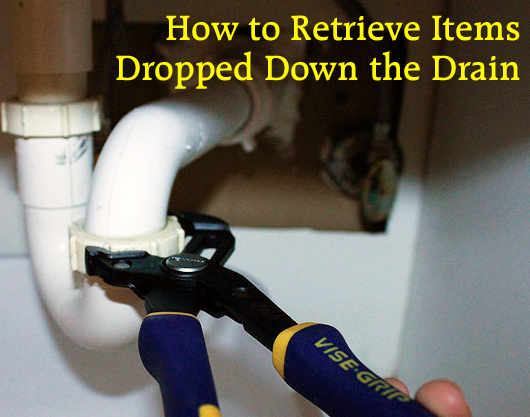

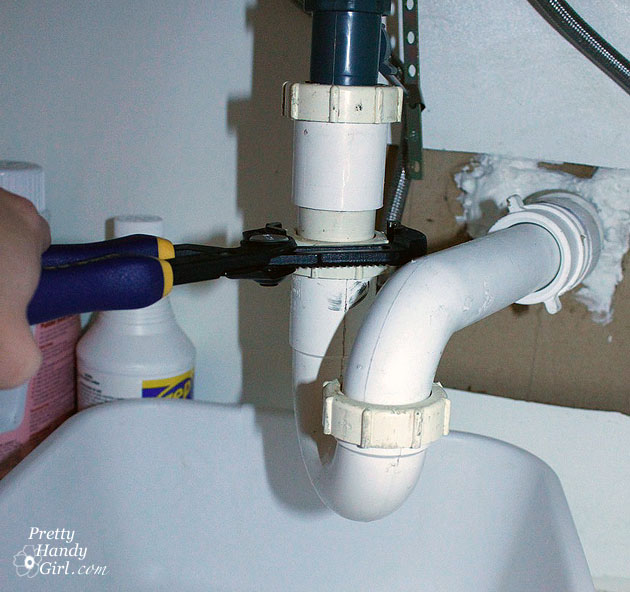

- Plumber’s Wrench (must have a wide mouth opening. The Irwin pliers shown have just enough of an opening to work)

- Adjustable Crescent Wrench

- Handsaw (drywall, coping or hack saw will work. Needs to cut through PVC)

- Flat head screwdriver

- Level

- Scissors

- Bucket or basin

- Sponge

- Rags or Towels

- Rubber Gloves

Disclaimer: This tutorial is a general overview of replacing a fill valve in your toilet tank. Be sure to follow the directions that come with your toilet parts as there may be changes or additional steps.

If you haven’t done so already, start by turning off the water. There should be a water shut off valve in the wall behind your toilet. Gently turn the knob clockwise to shut the valve.

Next, flush your toilet to drain the water from the tank. If your tank re-fills the water is not completely shut off.

Remove the lid to your tank. Set it in a safe place where it can’t get dropped and broken.

If there is still a lot of water in the bottom of the tank. Lift the flapper chain to drain the tank to the top of the flapper.

Use a sponge to completely soak up all the water remaining in the tank.

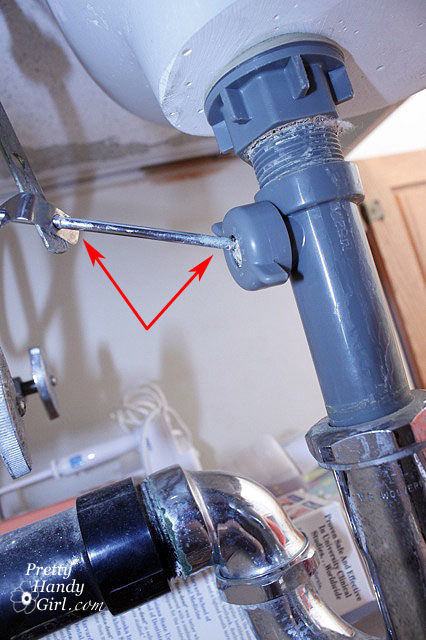

Once the tank is completely empty we can start to remove the fill valve. Look underneath the tank to see where the water line feeds into the tank. Using pliers, loosen and then remove the coupling nut from the supply line.

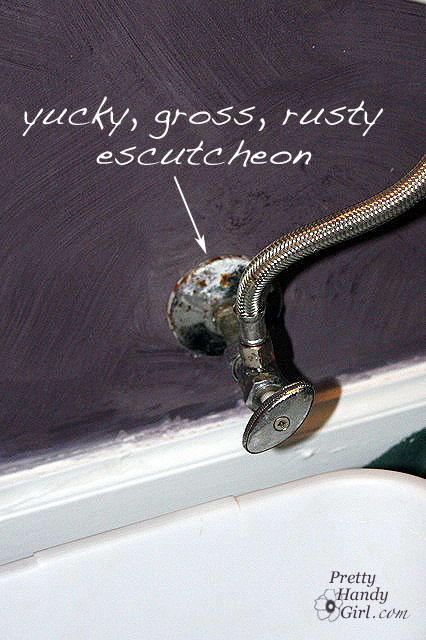

One quick note about supply lines: If your toilet has a plastic or rubber supply line, you should consider replacing it with a braided metal supply line that is less prone to breaking or leaks (in other words they can cause a major flood!) The same advice applies to the water lines under your sink and definitely your clothes washer.

Place the basin or bucket underneath the supply line and gently remove the line from the bottom of the fill valve (gray threaded stem shown below.)

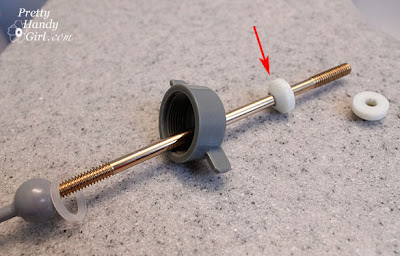

Remove the washer holding the fill valve to the tank.

Inside the tank, locate the small rubber hose that attaches the fill valve to the overflow tube. Then disconnect the hose as shown below.

Now you should be able to lift the fill valve up and out of the tank.

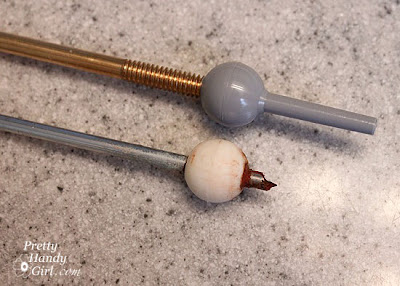

Place the new fill valve into the tank where the old one was. Notice the sleek new design, No Float Ball!

Side Note: You may need to adjust the height of the fill valve to fit in your tank. If so, twist the top portion of the valve independent of the bottom half. (After you fill the tank, you can raise or lower the valve the same way if you need to adjust the height of the fill valve.)

Thread the new washer onto the bottom of the fill valve where it extends out the bottom of the tank.

Gently tighten the washer, but be careful not to overtighten, or you might break the tank.

Next thread the coupling nut back onto the bottom of the fill valve to secure the water line.

Add the fill valve water hose onto the side of the fill valve. Then measure the distance to the top of the flush valve. Leave an extra inch, and trim any excess hose.

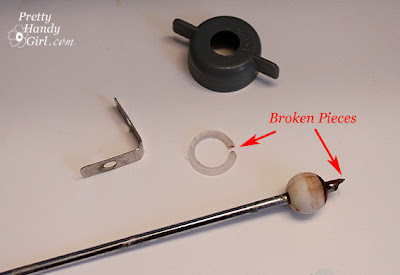

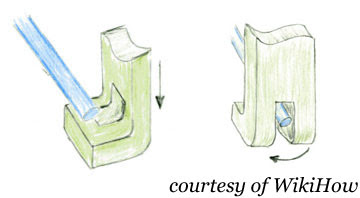

Find the anchor clip that attaches the hose to the overflow tube.

Slide the hose onto the clip and attach it with a hose clamp (if included with your kit).

Attach another hose clamp to the end of the hose where it meets the fill valve. Slide the anchor clip onto the top of the overflow tube. The hose should be free of kinks and should arch up as shown.

Before you turn the water back on, you need to flush the fill valve to rid it of any foreign matter. Twist the top of the fill valve counter clockwise and lift up to release it.

Place a bucket or cup directly over the top of the fill valve. This will re-direct the water that is going to spray straight up out of the fill valve.

Gently turn on the water supply while holding the bucket. Let it run for a few seconds, then turn it off again.

Replace the cap of the fill valve by setting the cap back on top and then twist the cap clockwise. Make sure it is on securely. Then turn the water supply back on.

While the tank is filling, press down on the float cup until it is submerged under water for 30 seconds. Then release. Now you can adjust the water level adjustment screw until the water in the tank is about 1″ lower than the top of the overflow tube.

Test your toilet by flushing it a few times. Does it work?! Hooray! You’ve now replaced 2/3 of your toilet tank parts. Next up, how to replace the overflow tube and flapper assembly.