Toilet Repairs – Part 3 – Replacing the Overflow Tube and Flapper

I’ve received a few emails and comments letting me know that some of you are going to try to repair your toilets! I just wanted to say, way to go! Plus, some of you had a few questions for me as well.

Here are the questions:

1. Our 1/2 bath toilet seems to chronically clog. We use enzyme stuff to clear it but it just clogs again the next time someone does anything substantial in it. It’s annoying. Any tips?

A. Adjust the amount of water in the tank so it will give more H20 to flush (as shown at the end of Toilet Repairs Part 2). Or use a good accordian style plunger:

If all else fails, you may have a clog and need to snake your toilet out. I’ve seen some snakes that attach to a drill.

Just be careful you don’t scratch the bottom of your toilet bowl when snaking it.

2. What are the symptoms for needing a new fill valve? On ours, you have to push the flush handle down really hard and hold it… or it won’t flush at all on first flush sometimes. Thanks for the great tutorials!

A. It sounds like you either need a new flapper or you might try tightening the chain between the flapper and the lever rod. If you need to replace the flapper, you should probably replace the entire overflow tube/flapper assembly.

And that leads me to today’s tutorial!

How to replace the overflow tube and flapper:

In review, here is what your toilet tank parts are:

And here is the kit I recommend you purchase (costs about $20):

And here are the tools you will need:

- Plumber’s Wrench (must have a wide mouth opening. The Irwin pliers shown have just enough of an opening to work)

- Adjustable Crescent Wrench

- Handsaw (drywall, coping or hack saw will work. Needs to cut through PVC)

- Flat head screwdriver

- Level

- Scissors

- Bucket or basin

- Sponge

- Rags or Towels

- Rubber Gloves

Disclaimer: This tutorial is a general overview of replacing an overflow tube and flapper in your toilet tank. Be sure to follow the directions that come with your toilet parts as there may be changes or additional steps.

If you haven’t done so already, start by turning off the water. There should be a water shut off valve in the wall behind your toilet. Gently turn the knob clockwise to shut the valve.

Next, flush your toilet to drain the water from the tank. If your tank re-fills the water is not completely shut off.

Remove the lid to your tank. Set it in a safe place where it can’t get dropped and broken.

If there is still a lot of water in the bottom of the tank. Lift the flapper chain to drain the tank to the top of the flapper.

Use a sponge to completely soak up all the water remaining in the tank.

Once the tank is completely empty we can start to remove the overflow tube and flapper. But, first you need to disconnect the water supply tube. Because TODAY we are going to take the entire tank off! Don’t be freaked out, you can do this. It is just like unscrewing the screws and removing a light switch cover (only it weighs a lot more.)

Look underneath the tank to see where the water line feeds into the tank. Using pliers, loosen and then remove the coupling nut from the supply line.

One quick note about supply lines: If your toilet has a plastic or rubber supply line, you should consider replacing it with a braided metal supply line that is less prone to breaking or leaks (in other words they can cause a major flood!) The same advice applies to the water lines under your sink and definitely your clothes washer.

Place the basin or bucket underneath the supply line and gently remove the line from the bottom of the fill valve (gray threaded stem shown below.)

Detach the chain from the lever rod inside the tank.

Remove the rubber gasket by lifting up the sides of the flaps. If your gasket is attached a different way, don’t worry about it, just leave it attached.

Disconnect the water refill hose from the overflow tube by sliding the anchor hook up and off the overflow.

Use your flat head screwdriver to lose the bolts at the bottom of the tank (on either side of the flapper.) You may need to reach underneath and hold the nut (or wing nut) with pliers as the bolt begins to loosen.

Once the nut (or wing nut) has been removed, you can now lift the tank off the toilet (using both hands.) Ask for help if you are concerned about possibly dropping the tank.

I recommend draping a towel over the toilet seat lid to rest the tank onto.

Remove the rubber gasket in the center of the underside of your tank. You may want to wear gloves (not because of germs, but because the rubber may be deteriorating and can leave black on your hands. But, come to think about it, I have two little boys and their aim isn’t exactly spot on. If you know what I mean.)

Now you need to remove the two bolts that held the tank to the toilet base. Loosen the nut with the pliers or crescent wrench.

Remove the nut and washer.

Repeat to remove the other bolt.

Grab the pliers and loosen the large plastic hex nut that was under the gasket. Then remove the nut. (I’m very thankful that the Irwin Adjustable Hex pliers I have worked perfectly. Otherwise, I would have had to buy a pair of plumbing pliers.)

Now you can remove the overflow tube and flapper assembly from the tank.

If you are replacing all the parts in your tank at once, when the tank is empty is a great time to give it a good cleaning!

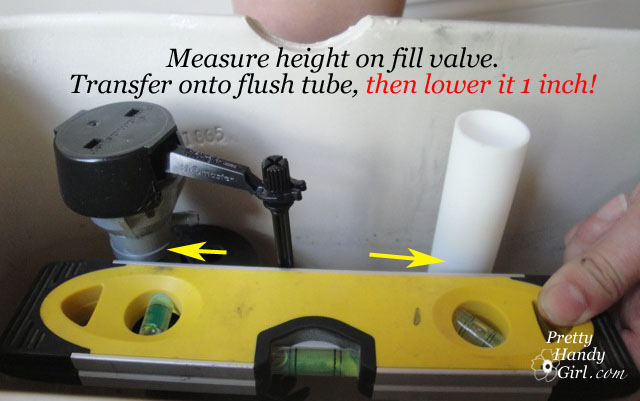

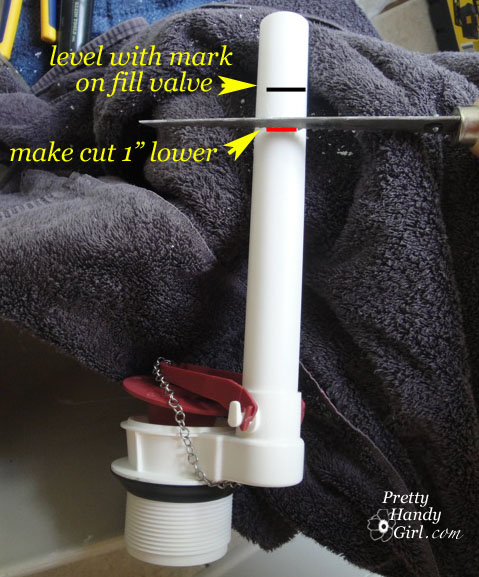

Okay, time to put Frankenstein back together again. Grab the new overflow tube and flapper assembly from your kit. Insert the new overflow tube back into the toilet tank. Make sure it is sitting flush against the bottom of the tank (you may need to tilt the tank for it to feed all the way through.) Then set your level up to the line indicated on the fill valve. Make a mark on the overflow tube one inch lower than the mark on the fill valve..

Cut the top of your overflow tube off using a saw. Sand any rough edges if necessary.

Re-insert the flush valve (overflow tube & flapper assembly) into the tank.

Thread the new hex nut onto the bottom of the overflow tube and hand tighten it.

Because I don’t possess the masculine type strength, I use my pliers to turn the hex nut another half a turn until it is snug but not tight enough to crack the tank.

Fit the new rubber gasket over the hex nut as shown below.

Insert two new bolts into the tank with a rubber washer just below the head of the bolt.

Thread a metal washer and a nut onto the bolts from the underside of the tank.

Gently tighten the nut with the crescent wrench. I can’t stress enough how important it is not to overtighten the nut. Or you will crack your toilet tank.

Repeat the same steps to insert the other bolt. The bottom of your tank should look like this:

Carefully replace the tank back onto the toilet base. Being sure to line up the bolts with the holes on the toilet.

Set a level on top of the tank and level it.

Thread the rubber washer, metal washer and then the new wing nut onto the bottom of the bolt. Tighten the wing nuts on both sides. All the while keep an eye on the tank to make sure it stays level.

Attach the flapper chain back onto the lever rod. Make sure there is a slight amount of slack in the chain, but not too much. Trim any excess chain that hangs too close to the flapper.

Turn on the water supply to refill the tank. Test the toilet by flushing it. Make sure the flapper closes and nothing holds it open. Replace the tank lid and enjoy your fully functioning toilet!

Hey, thanks for sticking with me through this “ugly” but necessary tutorial series. Hopefully I haven’t scared you off (judging from the very few comments I received.) I promise I have some more “attractive” tutorials coming soon. Then you can bring back your wonderfully sweet comments.

This is a great tutorial. My toilet is from 1957, the same age as the house. I replaced both the fill valve and flush valve successfully, but everything was rusted solid, so I ended up using a sawzall.

You’ve done a good job showing how to do your toilet,however you forgot to mention a very important step with the over flow tube.

My problem is with the two plastic nodules that hold the flapper in place,if you don’t line up the two nodules properly once you have re-assembled your tank the flapper will be crooked and not seal properly over the hole,that’s my problem,the toilet constantly drips.

I was hoping you could just turn the over flow tube to line up the flapper so it seals properly,and I have a funny feeling if I just loose the two bolts and twist the over flow tube to line up the flapper I will probably ruin the gaskets and have a worse problem.

I gather to turn the over flow tube I’m going to have Frankenstein the toilet to get to the big hex nut to loosen the tube.

I have no idea who worked on the toilet but I think he didn’t put the flapper on first to make sure it was going to seat properly.

Does my theory sound correct.

You should mention this in your video.

Paul, that’s a probably theory, but honestly if you are going to take the tank off go ahead and replace all the parts. They don’t last very long (especially if you have hard water.) At a minimum, just replace the flapper and overflow tube.

Thanks for tutorial. My toilet had been intermittently running and water was running out to flapper. It wasn’t bad but the trickling was driving me crazy. At first I thought it was a flapper them a valve issue. Turns out the overflow tube was broken at the base just above flapper. Went to Lowe’s followed your tips. Problem solved. First time I separated toilet bowl from seat. Who new it was that easy. Thanks again. Matt

This is great to hear Matt! Congratulations.

Thanks!

One of the very few explanations I found online that has useful pictures of all the important steps and clear explanations… instead of long videos of useless chatter.

Turns out my problem was that the instructions for the kit I have gave the wrong order of washers&nuts to fasten the tank to the bowl. But when I do it your way, it doesn’t leak!

You are wonderful. I used your instructions to completely replace the innards of my mom’s toilet and it has never worked better. Thank you so much.

Thank you so much for letting me know and a big virtual fist bump to you girl!

Help! I have replaced all the parts in the tank and everything seems to work perfectly, after flushing the tank will fill to right level and stop. I see no leaks or anything but a couple of hours later the water level has risen above the overflow pipe and starts dripping into the toilet. This was the reason I replaced all the parts originally . Do you have any idea what could be causing this?

Have you tried lowering the float so it won’t fill as much?

Excellent detail. The step-by-step is very helpful.

To the lady who asked the first question about the constant clogging: She may have had someone come in and replace the “guts” of an old toilet (3.5 gal flush) with newer components which are made for the low-flow toilets. (Don’t get me started on low flow toilets and the damage they have done in cities that have a long run to the sewer main!!!!!)

Be very careful with just replacing things. If you have an older toilet, ALWAYS consider repair (and even fabrication of a component) before replacement.

Your relationship together with your child will be the longest and many

important relationship you may ever have. Many solicitors

practice over different areas of regulations, nevertheless you may think

that it is safer to retain an attorney that is a professional

on divorce. When looking at the economics only,

however, forgetting about the emotionality, there ought to be almost no fighting relating

to the spouses on this particular subject as

it is often usually always better, particularly in a declining market, for starters spouse to permit the opposite to keep your family residence to acquire being bought out.

Thanks for the advice, photos, steps, and encourgagement.

However, in my case it was not as easy as a light switch cover because one of the bolts holding the tank to the base was frozen. We had two people, my partner holding the wrench on the nut below and me with a giant screwdriver on the top. The tools were not slipping, but our combined might did not break the grip the nut had on the bolt, even with some Liquid Wrench on it.

I finally got out my Dremel tool that I have for crafting and put a cutting disk on it. I tried cutting a slot in the nut. I didn’t get all the way through, but maybe the vibration got the Liquid Wrench working because eventually it gave and we got it out. And the kit had two fresh bolts.

1/2 the time I flush the toilet the flapper doesn’t go in the hole and my toilet runs, which makes the water company very happy but not me, Please help me, what is the problem?

Rose, did you follow this tutorial and install a new flapper and overflow tube? If so, you might need to try a new one. Or check to make sure the chain attached to the handle isn’t getting caught in the flapper.